Client Overview

The client is a leading manufacturer of electric vehicle (EV) chargers, delivering high-performance charging infrastructure to global markets. With rapid EV adoption and expanding deployment networks, the organization focused on strengthening system performance, operational safety, and long-term reliability.

As part of its Industry 4.0 manufacturing roadmap, the client aimed to build smarter, data-driven validation processes that ensure every charging station performs consistently under real-world conditions supporting scalable growth and future-ready mobility.

Business Challenge

To remain competitive and compliant, the client required an advanced product testing solution that could:

- Ensure compliance with international safety and performance standards.

- Reduce downtime and maintenance costs through early fault detection.

- Guarantee optimal charger performance under real-world operating conditions.

- Support faster validation and deployment of new charger models

Solution by Exeliq Tech Solutions

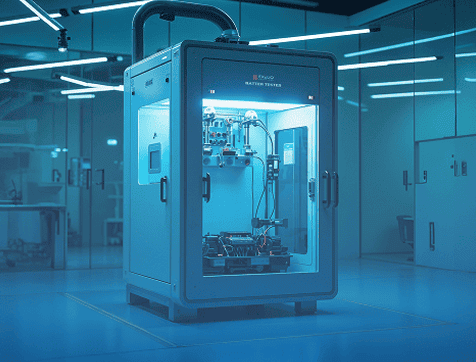

Exeliq Tech Solutions implemented a comprehensive Industry 4.0 enabled Automated Test Equipment (ATE) solution designed specifically for EV charger validation. The system combined automation, real-time data monitoring, and environmental testing to deliver accurate and repeatable results across all test stages.

Key Features of the EV Charger Testing System

- Programmable AC source up to 20 kVA for dynamic and variable load testing

- Multichannel power meter for detailed input/output analysis with advanced THD measurements

- Thermal and humidity chambers to simulate real-world environmental conditions

- Inbuilt CAN support for data packet verification and calibration

- HV/IR and withstand voltage testing to ensure electrical safety and insulation integrity

This integrated automated test equipment enabled end-to-end validation while supporting smart manufacturing and predictive quality control.

Results & Impact

The implementation of Exeliq’s product testing solution delivered measurable improvements:

- 30% improvement in charger reliability, significantly reducing failures during peak usage

- 25% reduction in maintenance costs due to proactive fault detection and early intervention

- 15% faster time-to-market, achieved through streamlined and automated testing workflows

- 40% increase in customer satisfaction, driven by improved charger performance and reliability

Client Testimonial

“Earlier, we were spending a lot of time troubleshooting issues after deployment. With this testing setup, we’re now able to catch problems much earlier. The data is clear, testing is faster, and overall reliability has improved noticeably.”

-Quality Manager, EV Charging Solutions Company

Key Takeaways

- Industry 4.0–driven product testing solutions are essential for scalable and reliable EV charger manufacturing

- Automated Test Equipment (ATE) enhances testing accuracy, efficiency, and repeatability

- Compliance with global safety standards builds customer trust and market readiness

- Early issue detection improves reliability, reduces costs, and strengthens overall business performance

More Case Studies

EV Motor Testing Solution Boosts Efficiency and Reliability

Learn More

Automated EV Controller Testing Enhances Efficiency

Learn More

How Our EOL Testing ATE is Safeguarding the Future

Learn More

Automated EV Cluster Testing Enhances Efficiency

Learn More