Client Background

Our client is a prominent manufacturer of cutting-edge inverters that are critical for power backups in every home. As part of their commitment to producing high-quality products, they needed a reliable, efficient, and scalable solution to test inverters at the end of their production lines.

Challenge

The client faced several challenges in maintaining the high standards of quality and functionality required for inverters used in every household:

-

1. Complex Testing Parameters: The inverters needed to undergo a range of functional and performance tests including voltage, current, frequency, power factor, and thermal efficiency.

-

2. Speed and Accuracy: Given the high volume of inverters in production, testing had to be fast without compromising accuracy.

-

3. Integration with Existing Systems: The new EOL tester had to be compatible with the existing manufacturing systems to ensure smooth operation.

-

4. Adaptability for Multiple Models: The solution had to cater to different inverter models, each with varying specifications and requirements.

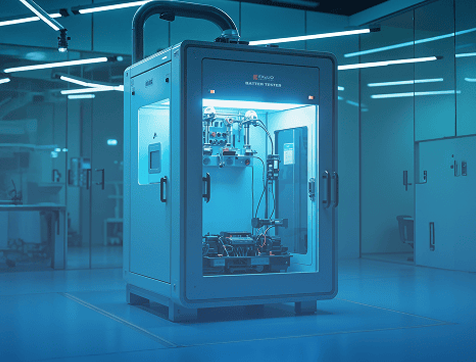

Solution Provided by Exeliq Tech Solutions

Exeliq Tech Solutions developed a sophisticated Inverter EOL Tester tailored to meet the specific needs of the client. The solution focused on speed, precision, and adaptability, ensuring that all critical parameters were thoroughly tested at the end of the production line.

-

1. Comprehensive Test Coverage

- Performance Tests: The system tested key parameters such as voltage output, frequency, power factor, and efficiency under simulated load conditions. This ensured that the inverters met both operational standards and performance expectations.

- Safety and Compliance Tests: Features like overvoltage protection, thermal efficiency, and short circuit detection were rigorously tested to ensure the products adhered to safety standards.

-

- The EOL tester incorporated automated sequencing for tests, allowing for rapid data collection and analysis, reducing manual operations and human error.

- The system was designed to reduce testing cycle times and improving testing efficiency.

-

- The tester was built with modular test configurations, allowing it to be easily reconfigured for different inverter models, making it future-proof for upcoming product lines.

- Integration with the client's existing MES (Manufacturing Execution System) ensured seamless data flow and minimized disruptions in the production process.

-

- The system featured real-time data monitoring, offering insights into test results, failure rates, and operational efficiency..

- Detailed reports were generated, providing documentation for compliance and quality audits, helping the client maintain their certification standards.

2. High-Speed Automated Testing

3. Scalability and Flexibility

4. Advanced Data Management and Analytics

Results

- Increased Efficiency:

The automated EOL testing system reduced the testing cycle time by 40%, allowing the client to increase production output without sacrificing product quality.

- High Precision and Quality Control:

The solution enabled precise detection of faulty inverters, with a 99.5% accuracy rate in identifying performance or safety issues. This significantly reduced the number of defective units in the field.

- Cost Savings:

The automation and reduction in error rates led to a 25% reduction in production costs, especially in terms of operator, re-transportation and rework.

- Seamless Integration:

The tester integrated smoothly with the existing production lines and MES systems, which ensured that there was no disruption in the manufacturing workflow.

- Scalability for Future Models:

The modular design of the tester allows for easy updates and configuration changes as new inverter models will introduce, ensuring the system could grow with the client’s evolving product portfolio.

Conclusion

The Inverter EOL Tester developed by Exeliq Tech Solutions proved to be an invaluable asset to the client, enabling them to meet the rigorous demands of high-quality inverter manufacturing. With enhanced testing efficiency, improved accuracy, and scalable solutions, the system not only addressed current challenges but also positioned the client for future growth.

More Case Studies

EV Motor Testing Solution Boosts Efficiency and Reliability

Learn More

Automated EV Controller Testing Enhances Efficiency

Learn More

How Our EOL Testing ATE is Safeguarding the Future

Learn More

Automated EV Cluster Testing Enhances Efficiency

Learn More